Modelling

Advanced modelling of our structures and how they are likely to perform in real-world conditions will increase the efficiency of our research. We aim to be confident in the success of a prototype before we construct and deploy it.

Working with the best in the business

Modelling methodology and capability is an extremely important component of the research and development process required to produce fit-for-purpose OOA structures.

New Zealand has some excellent modelling capability, but there are many researchers abroad equipped with better technology and resources to do modelling at the level required to support our research goals. We will work with the best in the business, both in New Zealand and abroad, saving time and money throughout the R&D process.

Advanced modelling capability

Researchers at Cawthron Institute currently use an OrcaFlex-based Finite Element Analysis computational modelling pipeline to provide insight on structural performance and conditions experienced by structures and farmstock.

During the structure design process, we can investigate load-evasive engineering, assess the feasibility of alternative materials (cost, durability, ease-of-use, environmental friendliness) with the aim of producing reliable, cost-effective, and robust designs.

When creating simulations, we will draw upon the expertise of one of our international Programme researchers, Dr Arndt Hildebrandt at the Ludwig Franzius Institute at Leibniz Universität Hannover.

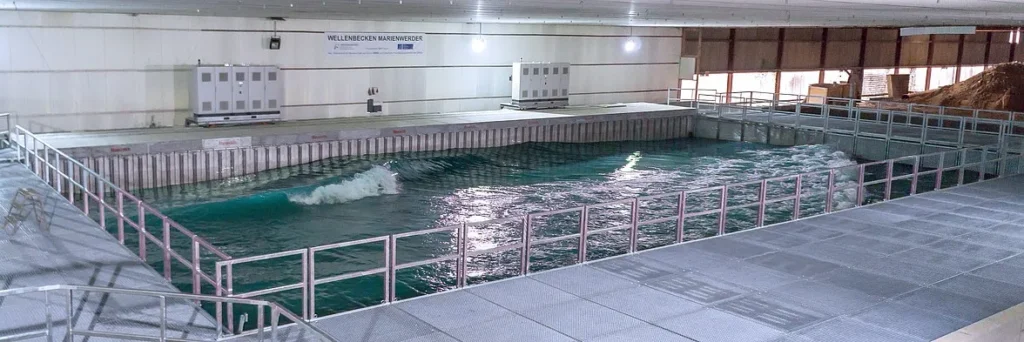

The LUFI is home to one of the most sophisticated simulation tools in Europe – a large-scale wave channel and basin where we will be able to test scaled versions of our structures in simulated real-world ocean conditions. This avoids the high costs of a trial and error approach testing full-scale prototypes at sea.