Monitoring

We want to know what's happening on our marine farms, in real-time, from the comfort and safety of dry land.

Sensors

It's not always possible or safe for farmers to get in a boat and head out to check on their marine farm in rough weather. It's also not efficient to go out regularly just for routine monitoring. If we want to farm in the open ocean, we have to have the sensor technologies that can tell us how our crops and structures are coping from the comfort and safety of dry land.

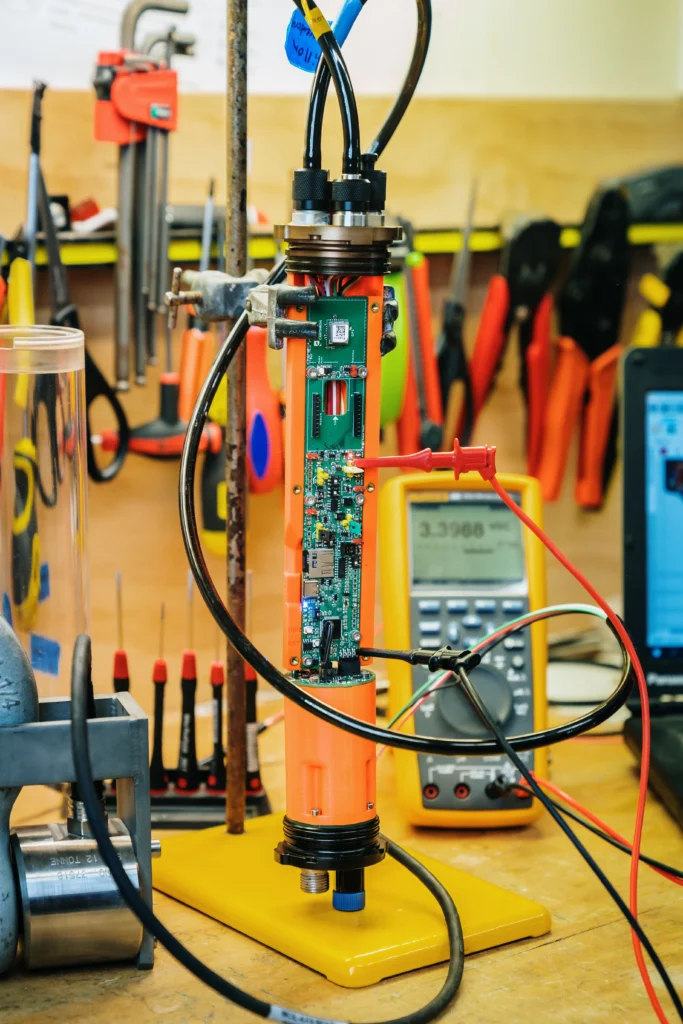

Cawthron Institute’s Blue Technology team have decades of experience in the development of remote sensor technology. Many of our Programme researchers have also been involved in the Science for Technological Innovation National Science Challenge’s ‘Precision Aquaculture spearhead project’, which has produced a variety of remote monitoring technologies they will refine during our research and development activities.

Our work on sensors will have two key purposes; Firstly these sensors will help us design, model and test our prototype structures and monitor species we plan to trial as OOA crops through the Programme’s R&D phase. This includes placing sensors on the structures that monitor load and movement sensors at strategic points, logging from 1Hz to 16Hz. The sensors log movement, depth, and acceleration relative to the orientation of waves and water currents. Not only will this enable us to validate our prototypes, but it will help us refine our sensor technologies so we know they will work in a real-world environment. We will also utilise sensors that monitor the crops themselves, like mussel hall sensors that measure gaping behaviour and can provide an indication of stress.

Secondly, we hope to address the challenge of the affordability and accessibility of remote sensor technology, as it is currently unavailable or too expensive. One of Cawthron Institute’s goals, which work through this Programme and our SfTI Ocean Intelligence Project will support, is to drive sensor innovation that is fit-for-purpose for aquaculture, providing farmers with digital tools for managing farms remotely. Our areas of focus include:

- Load cell sensors which measure the load or force being exerted on structures underwater.

- Temperature strings which measure the water column temperature from surface down the water column.

- Monitoring floats or buoys that measure currents, temperature, salinity, wave height, chlorophyll, and other important parameters.

- Biomonitoring sensors fixed to the crops themselves (e.g. hall sensors).

Buoys

Buoys are a key component of any integrated remote monitoring system, transmitting and receiving data from sensors back to shore.

Cawthron Institute has world-class capability in the development of monitoring buoy technology. Cawthron’s TASCAM coastal monitoring platform was the first buoy in New Zealand waters to use inductive instrument technology. This hi-tech buoy was developed in collaboration with the California-based Monterey Bay Aquarium Research Institute (MBARI). Cawthron has since developed a network of buoys located at open ocean aquaculture sites around New Zealand. These buoys record long-term information on simple but significant parameters like temperature, salinity, turbidity (sediment) and chlorophyll – all indicators of the quality and productivity of our coastal waters. This information is also useful for farmers because it informs farm management practices.

In the context of this Programme, the data collected from Cawthron monitoring buoys will be used to calculate ‘gross sea conditions’ (magnitude of waves and water currents) and inform modelling exercises so we know we are designing to real-world conditions. We will build and deploy a third buoy in the Firth of Thames at our proposed test site once consent is approved.

Cawthron researchers involved in Ngā Punga o te Moana are experts in the development of ‘base station’ floats on mussel lines that have integrated IoT ‘temperature string’ sensors, logging cameras, load cells, and other types of sensors designed to enable remote monitoring.

We have several floats already deployed on mussel farms in the Nelson/Marlborough region. Through this Programme we plan to refine float design so that it contains a small, sealed generator incorporated into operational floats for powering sensors to (initially) monitor mussel rope movement and mussel feeding activity. The information collected by these floats will help us assess the influence of structural design and orientation on structural integrity, shellfish behaviour, and ultimately production.